Performing an interfacial tension measurement

between water / oil according to ASTM D971 standard.

1. Check the instructions in section 5.1 and make necessary preparations.

2. Set oil density to correct value. You may also measure the density of the

oil (see section 5.2).

3. Make sure that the correction method of your preference is selected. You

can change the active ring correction method from Adjust parameters

menu. To be strictly compliant with ASTM D971 standard, choose

Zuidema-Waters. However, Huh-Mason is a more modern method that is

generally regarded more accurate.

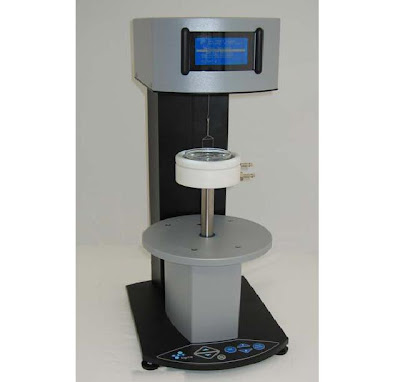

4. Pour distilled water at a temperature of 25 ± 1°C into cleaned sample

container to a depth of 10 to 15 mm. Place it in to the middle of the

tensiometer platform. Make sure no foam is present at the water surface.

If foam is visible, discard the water. Foam indicates that the water is

contaminated or that the vessel is not clean.

5. Mount the ring in the tensiometer hook. If the oil to be measured is denser

than water, the measurement must be performed in Push Mode1, and the

supplied weight therefor needs to be attached to the ring before mounting

the ring.

6. Select "Measure oil interface" from the menu selection and press the OK

button. Sigma will now measure automatically the surface tension of the

water. Wait until the measurement has completed. If the measurement

was successful, the ring will automatically descend back into the water,

except in the case of Push Mode measurement with dense oil, however,

the ring will remain about 5 mm above the water.

7. When the ring has stopped moving, carefully layer the oil on the surface of

the water, until an oil layer of at least 10 mm is reached2. Do not move

the sample container from tensiometer platform, nor move the ring.

8. Press the OK button right after the oil pouring is finished. The tensiometer

will then wait for 29 seconds (as the standard requires a wait between 29

and 31 seconds), until it starts the measurement of the interfacial tension

between water and oil. Wait until the measurement has completed.

9. Interfacial tension value is shown on the display.

As the ring is pulled through a surface or an interface, a curve is plotted,

showing the tension value calculated from the balance reading at each

instant. The highest value encountered will be displayed as the result of the

measurement.

1 If the oil is denser than water, it forms a layer below water and interfacial tension must

measured by pulling the ring downwards from water to oil; hence the name Push Mode. The

case of Push Mode measurement is not explicitly addressed in ASTM D971 standard.

2 Layering the oil should not take more time than 30s since completing the entire interfacial

tension measurement have to be done within 60s ±10s

No comments:

Post a Comment