Electronics industry provides electrical circuits involving active electrical components. Integrated circuits that are used in electrical and electronic devices are built on wafers made of semiconductor materials. Silicon is the most used semiconducting material. Silicon wafers are made of extremely pure silicon, which requires a high quality control. Polymers are also used in the electronic industry as insulating layers in the fabrication of chips and chip carriers. By using our product brand Attension, Tensiometry can be widely utilized in the electronics industry to characterize different material properties.

Application examples include:

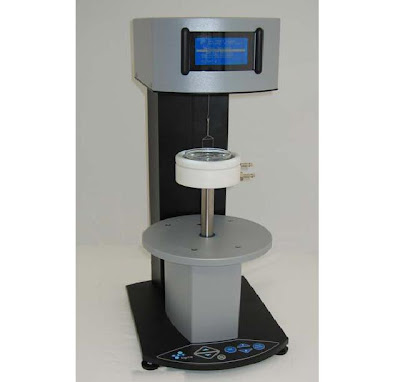

• Cleanliness of silicon wafers and circuit boards is an important factor to ensure the optimized functionality of the final product. Contact angle measurements with optical tensiometers can be used to study cleanliness of silicon wafers and circuit boards during the manufacturing process. • Semiconducting wafers are typically processed with protecting coatings. Quality and uniformity of these coatings can be studied with contact angle measurements. • Wettability and interfacial tension are important characteristics of soldering systems used in electronics industry. The molten solder alloy needs to wet both metal surfaces in order for the surfaces to link. Wettability of molten solder on metal can be defined by contact angleforce tensiometer. measurements with